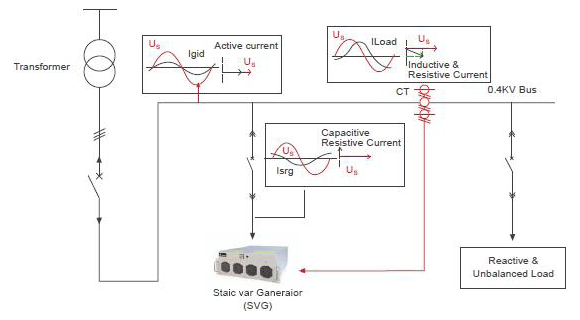

Static var generator/SVG/STATCOM is the new standard in reactive energy compensation. This power electronic current source is the accurate and highly reliable solution for today’s networks characterized by significant increase in harmonics, voltage variations caused by intermittent renewable sources connected to the network and voltage level due to the smart grid development. The DSP controlled IGBT topology enables a perfect compensation on each phase for both inductive and capacitive loads. It also correct phase unbalance where necessary. Immune to harmonics, resonance and voltage level, it offers a maintenance free solution reusable in any network configuration.